ODC creates software engineering insights through leveraging information trapped in the defect stream. Design changes, QA issues, trouble tickets .. are fed into the ODC system which turns them into insightful measurements on the product and process. This has worked on a small teams of 10 and a telecom network project with 1000 engineers.

.. brings AI to Root Cause Analysis and makes it 100x better.

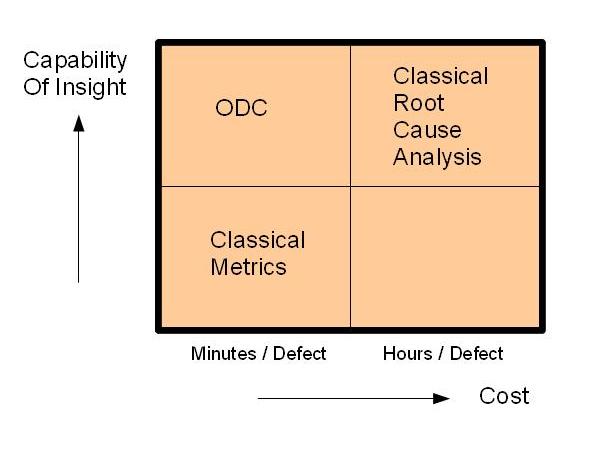

The X axis captures cost in terms of time spent per defect for analysis.

The X axis captures cost in terms of time spent per defect for analysis.